26

DECEMBER 2014

•

WORLD AQUACULTURE

•

WWW.WA S.ORGlocated in Kubu, Bali raises specific pathogen-free

L. vannamei

in

ponds, applying basic biofloc technology with no water exchange.

Ample aeration and well-controlled dissolved oxygen concentration

maintained good water quality in the culture environment. The farm

has produced 45-55 t/cycle since 2009 in a stable and sustainable

way from 12 small concrete ponds with a total surface area of 2

ha (Taw and Setio 2014). The technology also has been applied in

super-intensive raceways production as high as 9.9 kg/m

2

(Samocha

et al

. 2012) and 7.5 kg/m

3

(Otoshi

et al.

2006).

The technology was applied for other species of shrimp, such as

P. monodon

in Australia by CSIRO in 2008 and freshwater prawn

Macrobrachium

in India. It has also been applied in blue shrimp

L. stylirostris

broodstock production (Cardona

et al

. 2014). That

study compared two culture systems, clearwater and biofloc, and

confirmed that biofloc is beneficial to the reproductive performance

of blue shrimp broodstock and larval quality.

Biofloc Technology and Biosecurity

With emerging viral problems and rising costs for energy,

biosecurity with biofloc technology appears to be an answer for

sustainable production (Table 4). Large shrimp farms, which

initiated biofloc technology in Sumatra, Indonesia from late 2002 to

2007, have not experienced any WSSV outbreaks (Taw 2010).

As at other farms in the vicinity, Arca Biru shrimp farm,

Blue Archipelago Berhad was faced with serious outbreaks from

white spot syndrome virus (WSSV) before the redesign. During

its first new cycle, viral incidents were common in the vicinity. On

one occasion, dead WSSV positive shrimp were found within the

main supply canal. Despite this, the production cycle was a success,

without viral outbreaks (Taw

et al

. 2011)

A large-scale “integrated shrimp aquaculture park” (iSHARP)

project started by Blue Archipelago Berhad in Malaysia in 2009 had

a goal to complete over 600 ponds and reservoirs for raising Pacific

white shrimp on 1,000 ha of land at Setiu, in the state of Terengganu,

northeast of Kuala Lumpur. The first stocking was initiated in

October 2011. A total of 144 ponds were in operation by mid-

November 2012. No incidents of white spot syndrome (WSSV) or

early mortality syndrome (EMS) have been reported at the facility

(Taw

et al

. 2013) (Fig. 6).

The small family-owned shrimp farm located in Bali referred

to previously has produced shrimp continuously since 2009 in a

stable and sustainable way without WSSV and IMNV outbreaks

(Taw and Setio 2014).

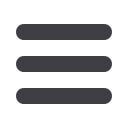

TABLE 1. Basic management concepts in shrimp culture.

TABLE 3. Comparative performance and technical

features of intensive biofloc and greenwater systems

for shrimp.

TABLE 4. Biosecurity attributes of biofloc systems.

TABLE 2. Desired concentrations of select water

quality variables in biofloc systems applied to

commercial shrimp farming.

VARIABLE

VALUE

NOTE

Salinity

20-35 ppt

Temperature 25-30 C

DO

> 4.0 mg/L

pH

7.3-8.4

Alkalinity

> 70 mg/L as CaCO

3

tends to reduce with

duration of culture

period

TAN

< 1.5 ppm

higher than

autotrophic system

NH3-N

< 0.1 ppm

higher than

autotrophic system

Nitrate (NO

3

) < 5.0 ppm

higher than

autotrophic system

PO

4

-P

< 2.0 ppm