WWW.WA

S.ORG

WWW.WA

S.ORG

•

WORLD AQUACULTURE

•

DECEMBER 2014

25

(29-30 percent) feed. Grain pellets

and molasses supply carbon as

needed to sustain carbon-to-

nitrogen ratios greater than 15.

Generally grain pellet applications

vary from 15 to 20 percent of the

total feed used during operations.

Molasses can be applied two or

three times weekly at 15-20 kg/ha.

Water stability of grain pellets is

between 15 and 20 minutes. This

provides an inexpensive organic

substrate for biofloc

to develop, in addition

to increasing the C:N

ratio.

Grain pellets are

a mixture of ground

wheat, corn and

occasionally soy, with

a protein level around

14-18 percent. Animal-

grade ground wheat

flour must be used. Using

grain pellets from wheat flour

as a carbon source results in

better yield, survival and FCR

of green tiger shrimp

Penaeus

semisulcatus

(Megahed 2010).

In addition to typical

chemicals such as dolomite

and lime, kaolin is required in

the preparation of pond water

and during operation. Kaolin

is the mineral kaolinite, a

hydrous aluminum silicate,

also known as China clay. It

is distinguished from other

industrial clays on the basis of

its fine particle size and pure

color. Its ability to disperse in water makes it an ideal pigment. Fine

particles of kaolin suspended in pond water are thought to become

nuclei of bioflocs in pond water. Kaolin is applied at 50-100 kg/ha.

Aerators help suspend bioflocs continuously in the pond water,

a main requirement for maximizing the potential of microbial

processes in shrimp culture ponds (Fig. 5). Especially in biofloc

systems, aerators need to be constantly monitored for malfunctions

and repaired or replaced without delay. Paddlewheel aerators keep

dissolved oxygen levels high. Dissolved oxygen levels must be

monitored frequently to keep levels greater than 4 mg/L. Water

quality should be managed within the limits indicated in Table 2.

Paddlewheel aerators need to be in the correct position

to promote accumulation of sludge in central areas of ponds.

Accumulated sludge at the pond center needs to be siphoned or

drained out periodically as needed. The required energy input

(horsepower of aerators) needs to be correlated to stocking density.

High stocking densities of 130-150 post-larvae/m

2

and high aeration

rates of 28-32 hp/ha are also

essential for expected production

of over 20 t/ha. Aeration

energy efficiency is 680 kg/

hp and can be as high as 1,000

kg/hp if partial harvesting is

implemented.

Performance of Biofloc

Systems in Commercial

Shrimp Farming

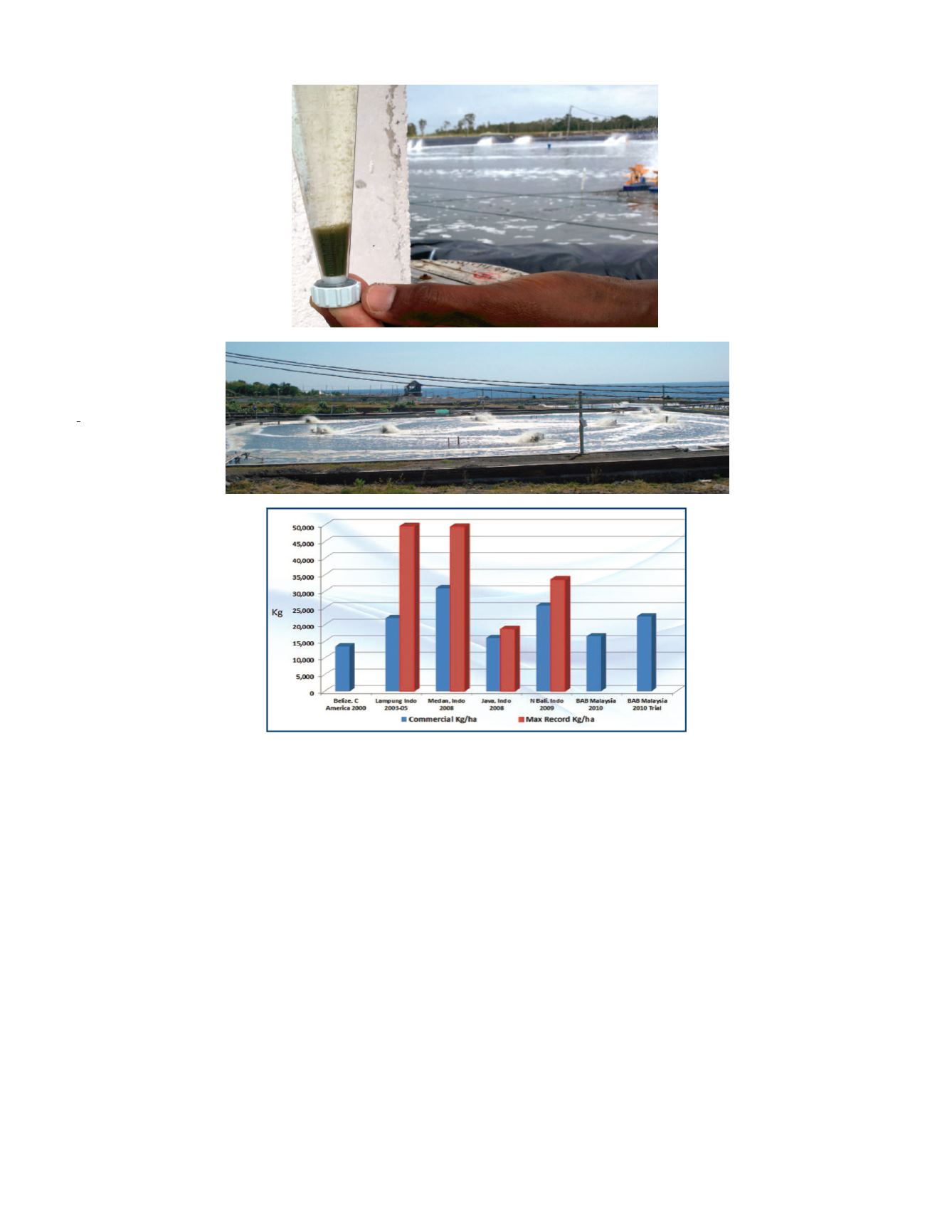

The technology has been

successfully applied

commercially

with shrimp

(L.

vannamei)

by

Belize Aquaculture

(McIntosh 2001).

Heterotrophic

bacterial

communities

facilitate the

production of high

yields (~15 t/ha per cycle)

in ponds with no water

exchange. It has also been

applied with success in

commercial shrimp farming

in Indonesia, achieving a

production of nearly 50 t/

ha in small research and

development ponds, and over

20 t/ha from commercial

ponds, with feed conversion

ratios between 0.98 and 1.30

(Table 3; Kopot and Taw

2004, Taw 2005, Taw 2010).

A combination

of two technologies,

partial harvesting and

biofloc, has been studied in northern Sumatra, Indonesia (Taw

et al.

2008). Production performance using partial harvest with

biofloc technology was greater than expected. One 2,500-m

2

pond produced 12.4 t (49.5 t/ha) through six partial harvests, with

a feed conversion ratio of 1.11. The technology was successfully

commercialized in Malaysia (Taw

et al

. 2011). For ponds lined on

dikes only, the shrimp farm averaged over 12 t/ha; for fully-lined

ponds with a semi-biofloc system, the average was over 16.2 t/

ha. Two ponds with biofloc systems averaged over 22.5 t/ha with

an average shrimp size of approximately 18 g. The outstanding

achievement was in a biofloc system with a stocking density of 130

post-larvae/m

2

, where shrimp reached over 18.8 g in just over 90

days of culture, with a production of over 22.5 t/ha (Taw

et al

. 2011).

A similar performance with a semi-biofloc system was recorded at

the iSHARP project in Malaysia (Taw

et al

. 2013, Fig. 6).

The small, family-owned Ndaru Luat Setio shrimp farm

( C O N T I N U E D O N P A G E 2 6 )

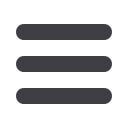

TOP, FIGURE 4.

About 5 mL/L of settled biofloc in an Imhoff cone. Moderate floc

densities are preferable.

MIDDLE, FIGURE 5.

Biofloc shrimp culture ponds must be

well aerated. Note number and positioning of aerators.

BOTTOM, FIGURE 6.

Shrimp

production in commercial-scale biofloc systems.