24

DECEMBER 2014

•

WORLD AQUACULTURE

•

WWW.WA S.ORGB

iofloc systems—a recent

technology—offer a promise of stable

and sustainable production, inasmuch

as the system is operated without water

exchange and so has an enhanced capacity

for nitrification within the culture ponds

(Avnimelech

et al.

2012). The main

economic advantages of biofloc technology

over greenwater (algae-based) systems

are higher growth rate, lower FCR and

sustainable production (Table 2).

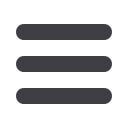

Bioflocs are

macroaggregates – diatoms,

macroalgae, fecal pellets,

exoskeletons, remains of

dead organisms, bacteria, and

invertebrates – suspended in the

water column (Fig. 1). Biofloc

can be used as a single-cell

protein source for shrimp and

fish. The crude protein content

of biofloc ranges from 35 to

50 percent, and the crude lipid

content is 0.6 to 12.0

percent by volume.

Biofloc can be slightly

deficient in arginine,

lysine and methionine.

The ash content ranges

between 21 and 32

percent.

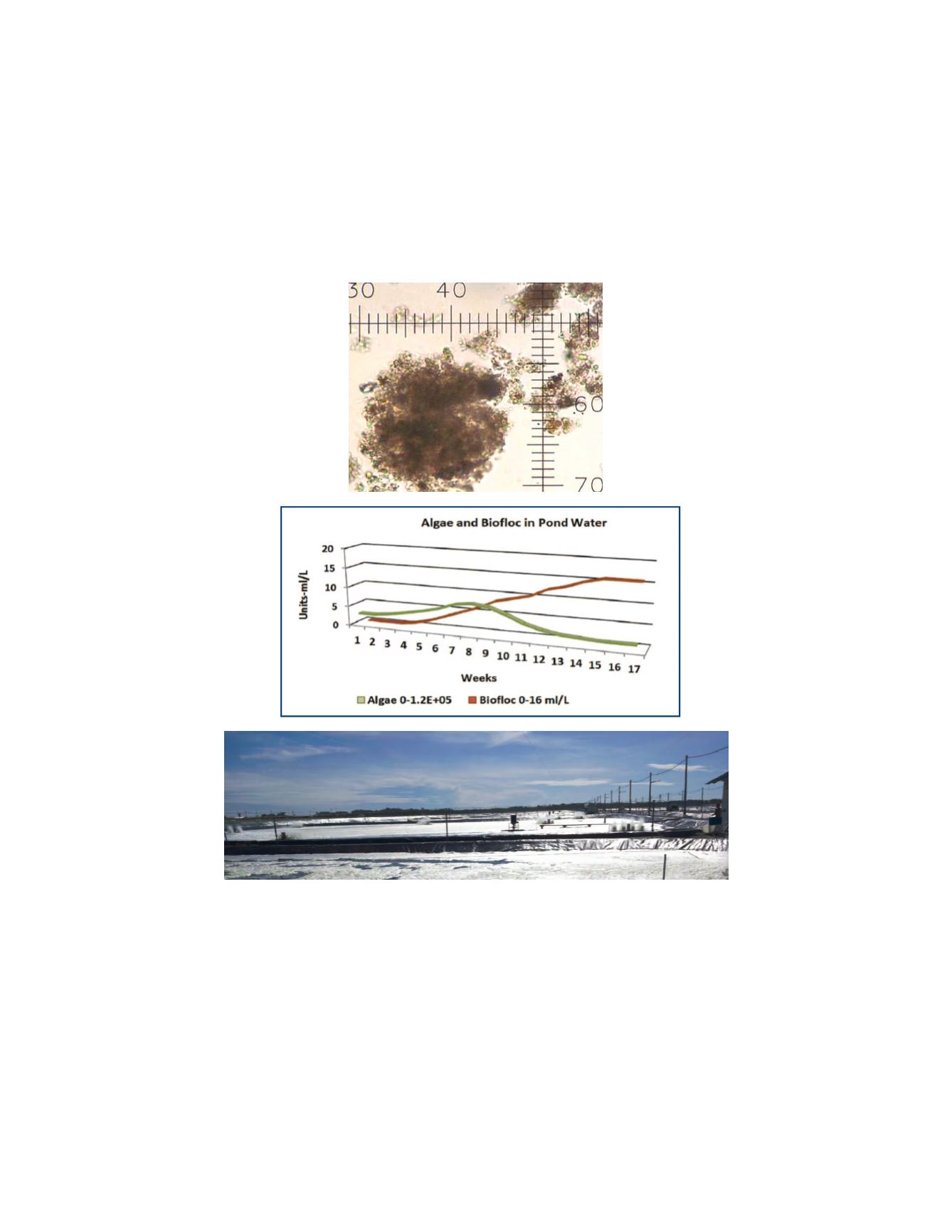

In biofloc

systems, algae develop

first, then a transition

period with foam

formation and finally

a brown biofloc

develops (Fig. 2 and 3).

This may take a few weeks or longer, depending on the biomass of

shrimp or fish in the pond. The transition occurs earlier with tilapia,

later with shrimp. Basically the systems starts with an algae bloom

and the biofloc community develops thereafter.

Advantages and Disadvantages

One of the main advantages of biofloc technology is high

biosecurity. To date, white spot syndrome virus has not been a factor

in biofloc systems. Production and carrying capacity are typically

Shrimp Farming with Biofloc

Technology: Commercial Experience

and Approaches to Disease Control

Nyan Taw

5-10 percent greater than in typical culture

systems with no water exchange. Shrimp

grow larger and reflect feed conversion

ratios between 1.0 and 1.3. Production

costs can be 15 to 20 percent lower.

A main disadvantage is the high

energy input for aeration. Power failures

of more than one hour in duration can be

critical. Biofloc ponds need to be lined.

The more advanced technology also

demands better training of technicians.

Brief Operating

Protocol for

Shrimp Farming

Biofloc technology

for shrimp culture on a

commercial scale and in

large ponds is simple and

yet, in a way, complex. Basic

conventional procedures,

depending on location and

situation of the farm, need

to be followed. The

procedure must

be adjusted with

changes in culture

water environment

and shrimp behavior,

such as health and

growth (Table 1).

For optimized,

sustainable

commercial biofloc

shrimp culture,

HDPE- or concrete-

lined ponds are basic

requirements. Only

specific pathogen-free post-larvae are stocked.

When ponds are stocked, a major factor to be controlled is

biofloc volume. Using Imhoff cones for assessment, biofloc volumes

must be maintained below 10 mL/L for full biofloc and 5 mL/L for

semi-biofloc systems (Fig. 4). A sample must be taken concurrently

from each of two locations below the water surface. Green or brown

water is acceptable, but black water is an indicator of abnormal

conditions. Suspended biofloc must be available as food for shrimp.

Shrimp can be fed high protein (35-40 percent) or low protein

TOP, FIGURE 1.

A biofloc macroaggregate.

MIDDLE, FIGURE 2.

Changes in the importance of algae

and biofloc in a production cycle for shrimp. Algae is more important in the first half and biofloc dominates in the

second half in response to high feed loading.

BOTTOM, FIGURE 3.

The transition from algae dominance to

biofloc dominance in biofloc shrimp ponds is indicated by the presence of abundant foam.