WWW.WA

S.ORG

WWW.WA

S.ORG

•

WORLD AQUACULTURE

•

DECEMBER 2014

21

Sludge Management

The perception of most farmers (64 percent) is that sludge does

not accumulate in raceways because it is carried out with the flowing

water. Thirty two percent of surveyed farmers declared that they

remove sludge from their tanks and dispose of it. Two said that they

simply dump it in the river. One farmer collects sludge and uses it to

fertilize agricultural crops.

Farmers allow sludge to accumulate in raceways and discharge it

all at once because this is the least labor and time consuming method.

Most farmers lower raceway water level after harvesting, increase

water flow rate and allow sludge to exit ponds and raceways and flow

into the Assi River. Nearly all (96 percent) of farmers do not gauge

the flow rate of water that runs through their raceways. Continual

sludge removal of sludge is better because sludge accumulation can

cause stress in fish and poor water quality (Cripps and Bergheim

2000). Continual removal of sludge was performed by only 32

percent of surveyed farmers.

Use of Chemicals and Therapeutants

Nearly all (96 percent) of surveyed farmers stated they clean and

sterilize tanks between crops. Potassium permanganate (KMnO

4

)

was mentioned most often (by 79 percent of farmers) as a sterilization

chemical. Most trout farmers apply potassium permanganate to

their tanks when they lower water levels after harvesting. Salt and

quicklime are other products applied to raceways between crops. Salt

was mentioned by 47 percent of farmers and 23 percent say they use

quicklime for their ponds. Many farmers do not know the difference

between permanganate, salt or quicklime as therapeutants.

To clarify, farmers use chemicals if they thought there was a

need, but generally do not use them. They followed cleaning and

sterilizing protocols mainly because other farmers do so. Some

farmers even use potassium permanganate as a drug and apply it

while fish are cultured. Such a treatment is an approved parasiticide

used elsewhere but flow rate and drug concentration are managed

strictly. Excessive use of potassium permanganate can harm fish and

low dosages are inconsequential to the parasites. In addition, farmers

often treat sick fish with permanganate without knowing if the

disease is viral, bacterial or parasitic.

Drugs used to treat the fish included Avytril (enrofloxacin,

fluorquinolone) and tetracycline, each used by 19 percent of the

farmers. However, those 38 percent are not the only farmers giving

drugs to their fish. Farmers generally do not know the names of the

medicines they use and some declare that they receive drugs them

with no label on the bottles.

A potential catastrophe in the making is farmers treating all

diseases with antibiotics (namely enrofloxacin and oxytetracycline),

without knowing if the disease was bacterial and with disregard

to the possible environmental harm of antibiotics. For instance,

enrofloxacin is not approved by the United States Food and Drug

Administration (Koc

et al

. 2009) and oxytetracycline inhibits

nitrification, a necessary detoxifying process in natural waters

(Klaver and Matthews 1994). Also, oxytetracycline was found

to be “so stable that a half-life cannot be determined” (Shao

2001). Thus, antibacterial drug residues may remain in ponds and

can be transferred from raceway to raceway and into the Assi

River. Antibiotic residues in cultured fish could adversely affect

consumer health, and indiscriminant antibiotic use can promote the

development of drug-resistant bacteria that may also affect humans

(Grave

et al

. 1990, Wu 1995, Beardmore

et al

. 1997, Shao 2001,

Zhang

et al.

2010).

“Knowing how to deal with disease outbreaks can mean the

difference between a successful business or going broke,” stated

Cain and Garling (1993). Farmmanagers rarely ask for technical

assistance from experts when there is a disease outbreak. Farm

managers along the Assi River mainly copy practices from other

farmers, without trying to find the scientific explanations behind

them. For instance, when NGOs provided farmers with non-labeled

drug bottles, farmers used those for any symptoms they noticed

on rainbow trout, irrespective of the drug. They know that these

treatments are ineffective and possibly harmful and thus hide the

medications they use. We were unable to obtain a list of drugs

distributed to trout farmers by the local NGO.

An Estimate of Aggregate Ammonia Loading from

Trout Farms

In addition to the farming skills a trout farmer should have,

he/she should also understand the environment. The farmer must

be a biologist and ecologist. He should understand the relationship

between the position of the farm on a stream and water quality

entering the raceways. Aquaculture, similar to any agriculture

practice, can be environmentally unfriendly if not properly managed.

The carrying capacity of any system should be estimated and

production levels of an industry controlled accordingly. There are no

estimates of sustainable trout production quantities for the Lebanese

portion of the Assi River so a preliminary estimate was made. The

estimate is based on farmers’ expectations of overall rainbow trout

production for the 2010 season (2,196 t). Assuming a FCR of 1.3, then

2,196 t of fish requires 2,855 t of feed. The feed used by fish farmers

contains 45 percent protein. For fish feeds containing a high level of

protein, the net protein utilization (NPU) is 40 percent. Hence, total

ammonia nitrogen (TAN) released into the Assi River from 2,855 t

of aquafeed would be:

TAN = (1.0 – NPU) × (protein / 6.25) × 1000

TAN = (1.0 – 0.4) × (0.45 × 2,854.93/ 6.25) × 1000 = 123,300 g

( C O N T I N U E D O N P A G E 2 2 )

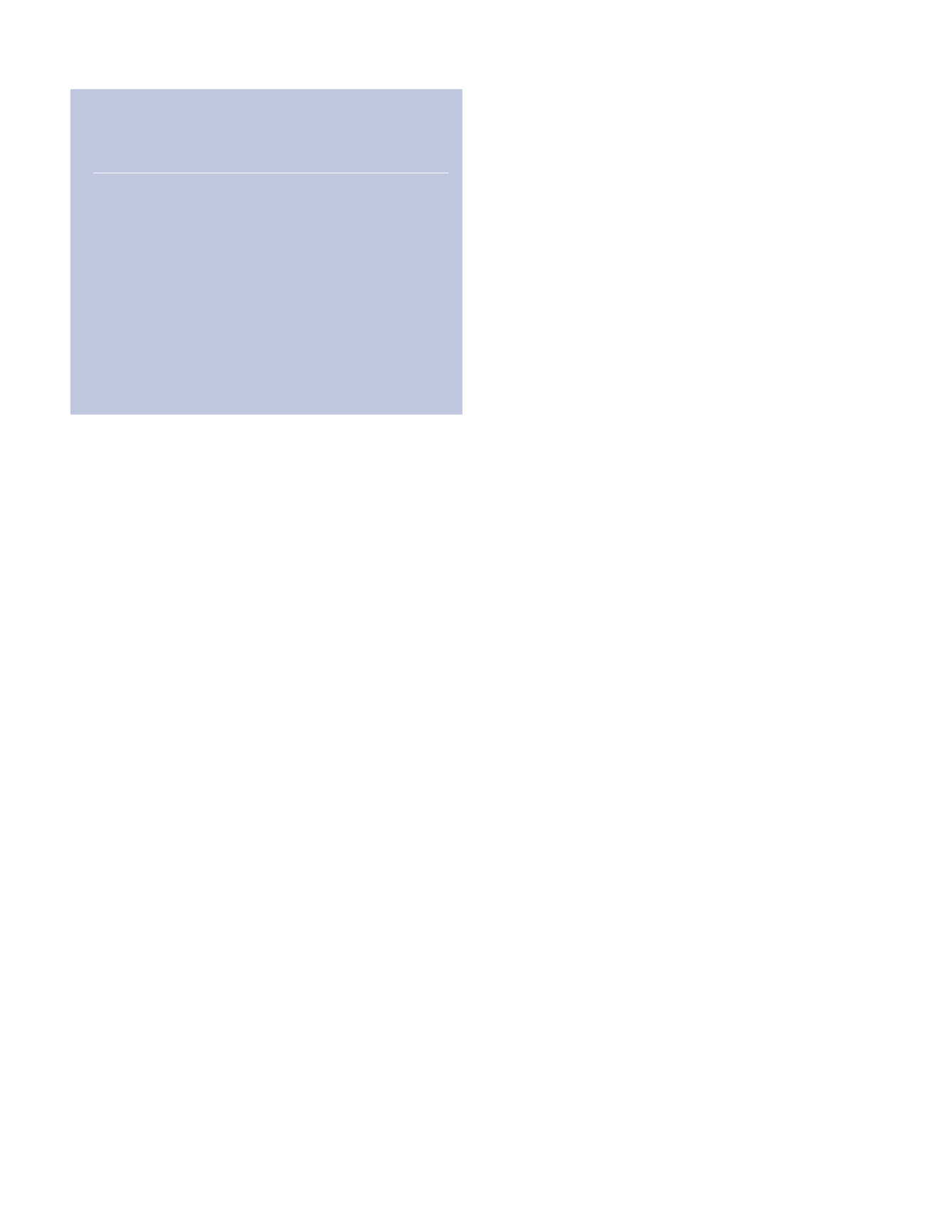

TABLE 2. Range of water quality parameters along

the Lebanese portion of the Assi River during

August, September and October of 2012.

WATER PARAMETER

RANGE

Conductivity (µs/cm)

303 – 368

Temperature (C)

15.1 – 16.2

Oxygen (mg/L)

7.72 – 9.78

pH

8.0 – 8.2

Alkalinity (mg/L)

200

Hardness (mg/L)

200

Ammonia-N (mg/L)

0.02 – 0.35

Nitrite-N (mg/L)

0.0

Nitrate-N (mg/L)

0.37 – 0.84

Phosphorus (mg/L)

0.06 – 0.18