Indonesia: Emerging as a Leader in Aquaculture

EDITOR’S NOTE: As you’ll note on page 6 of this issue, ASIAN PACIFIC AQUACULTURE 2024 will be held i...

Aquaculture is the fastest-growing food sector worldwide, representing a $250 billion industry, bringing to the table more seafood protein than traditional fisheries. As a unique alternative to the animal farming practices on land, where aquaculture development is limited by the competing requirements of urban development, forest cover and arable farming, among others, aquaculture has the potential to help meet demands without the same restrictions of ever-strained farming resources. To secure a sustainable future, however, aquaculture must ensure that scalability does not impact negatively on the stock species or wider marine environment. With an increasing global population and improving perception of seafood in diets, aquaculture must ensure that production yields are optimized, but also that the impacts of production are minimized and that the effects of other human activities on aquaculture are managed.

ABOUT THE ROUNDTABLE:

- Three rounds of discussions with participants from 21 organizations between July and September 2020.

- World Aquaculture Society (Chair), IMarEST (co- Chair), Adisseo, Assentoft, Biodiversity Connections, CEFAS, Chelsea Technologies, DHI (Singapore), FAO, Singapore laboratory Professional, National University of Singapore, Nautilus Collaboration, Net Your Problem, PCSGA, University of Glasgow, Ramboll (USA), Sea Sanctuaries Trust, SGS (Italy), SINTEF Ocean (Norway), Swanepoel International Law Specialist, University of Insubria (Varese, Italy)

- IMarEST: https://www.imarest.org/

- Contact: Guillaume.Drillet@sgs.com (WAS) and caitriona.hanly@imarest.org (IMarEST)

In particular, there is mounting evidence of the environmental impacts of plastics and marine litter, which are a growing public, political and academic concern. The aquaculture sector is having to cope with production and management of plastic waste, in addition to the implications that plastic pollution may have on wild stocks and potential health risks from harvested products. This is particularly true in Asia, where a very a large input of plastic waste emerges from a handful of countries (Philippines, Cambodia, Thailand and China). The continued growth of aquaculture highlights the need to address life cycle management of equipment and waste management. Unlike other sectors in the blue economy, aquaculture is likely to be most affected by the presence of meso-, micro- and nanoplastics in coastal waters, with a dominance expected for extractive aquaculture.

Aquaculture companies have started embracing developments as well as the policies that govern the use and the management of pathways of plastics in aquatic environments. However, there are knowledge gaps on the use or impacts of plastics in aquaculture, especially when existing reports regarding the sources of marinebased plastic emissions do not give clarification between fisheries and aquaculture. Despite aquaculture activities not expected to be a major contributor of plastic wastes compared to other industrial activities, at this stage, it is simply impossible to accurately reflect how aquaculture contributes to this environmental issue. However, aquaculture, like other productive sectors, needs to manage the use of plastics and minimize the impacts they may have wherever possible.

In preparation for a marine plastics session at the World Aquaculture Meeting (#WA2020) in Singapore, to be held in 14-18 June 2021, WAS and IMarEST coordinated a series of roundtable discussions to exchange information pertaining to the risks associated with plastics in aquaculture. The first event was held in July 2020 and this article outlines the main outcomes and identified areas that will be explored in greater depth during future roundtables. The July session brought together representatives from 21 organizations representing stakeholder groups that included academia, feed and feed additive manufacturers, testing and inspection organizations, NGOs and farmer’s associations.

To date, estimates by the FAO suggest that about 80 percent of plastic debris found in the oceans originates from land-based sources rather than from marine industries such as aquaculture, although it is recognized that marine industries can introduce various types of by the loss of fishing gear. However, without accurate data, it is complicated to manage the issue and develop policies to ensure improvements. The majority of the data extrapolated today comes from beach clean-up operations, coastal surveys and separation of waste to determine their origins. There are limitations, however, especially as these activities do not take place everywhere and are not necessarily conducted with the same methods or to the same scale.

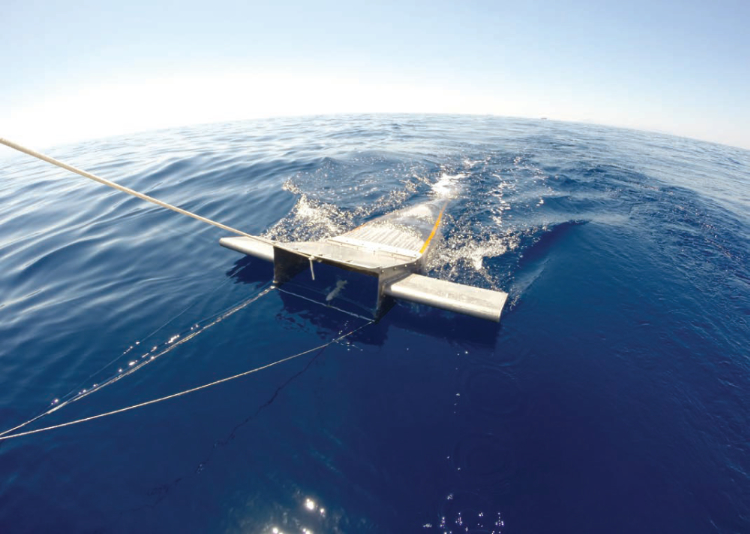

TOP: Material collected in a manta net from the Mediterranean Sea (2019). MIDDLE and BOTTOM: Material collect in the manta net is captured on a stainless-steel filter (10-μm mesh size), where larger plastic particles can be seen alongside small biota (Photos: Julia Farkas, SINTEF Ocean).

Being the fastest-growing food-production sector, aquaculture farms need to manage the quality and food safety of their products while minimizing the environmental impacts of production. As in all other food production sectors, the use of plastics by aquaculture, e.g. for equipment and packaging, is inevitably going to grow concurrently with the sector. In 2018, the Aquaculture Stewardship Council (ASC) recognized the importance of understanding the extent of plastic usage in aquaculture and the procedures for its management and disposal.

Plastics are used at every level of aquaculture production, whether it is for tanks, nets, feed bags, liners, piping, polystyrene boxes, product transportation or chemical storage. In addition, there are the general plastic products used daily by employees in many industries, such as plastic cups and drinking water bottles. Many of these products are considered essential for normal operations but, in many cases, farmers reviewing an inventory of products and materials are surprised by the volume of plastic waste they produce.

Categorizing the volume, location and use of plastics on a farm is an essential tool to offer a broader perspective on products and life cycle management to farmers and investors; this is referred to as an inventory of plastic usage. In general, the drive to evaluate the use of plastics is triggered by the request for ‘keeping a clean house’ coming from seafood buyers and societal perceptions (i.e. social insurance and social license to operate) and therefore this varies from one country to the next, depending on cultural perceptions of aquaculture operations and the stringency of regulations. Managing plastics in operations comes with planning and development of procedures, their implementation and responses to events where loss of gear and waste management failures occur.

During inventory exercises, the initial perceptions and assumptions regarding plastic use and waste are underestimated more often than not. The inventory can be used to map where alternatives to plastics can be used (e.g. wood, concrete, etc.), ultimately ensuring a decrease in the overall dependency on plastic material. It can also identify the specific needs of a given farm or company, for example, where open vs closed systems have different considerations for plastic wastes and risks for introduction into the environment. Producing plastic inventories can provide a great mechanism to raise awareness and form the basis for developing a dedicated general waste management plan (how much plastic, in which operation and how to dispose). These plans can then incorporate specific measures including, for example, an evaluation of the risk created by the degradation of the plastic product itself over time (see below). In some cases, the shelf-life of plastic structures can be regulated by government or associations, with recommendations given by equipment manufacturers.

Waste management plans for handling and disposal of solid wastes are mandatory in only some countries and farmers are asked to identify high-risk activities and materials that may result in introduced waste or represent a hazard for people. Incentivizing such behavior may be necessary in areas where there are grandfathering advantages for early movers, although it may simply be regulated and enforced in regions where the industry is fully developed and organized and the resilience of the production sector will not be too strongly impacted. For example, pre- and post-storm checklists are an important consideration for cage and rope production at sea, identifying suitable gear and points of risk. As climate change is driving more intense and more frequent storms, however, this is a challenge that could be addressed by marking or tagging gear for identification when lost. This approach is currently being tested in the commercial fishing industry.

There are lessons to be learned from the experiences of farmers who undertake inventories and activities such as post-storm checklists, to engender a cultural shift towards improved waste management. Typically, this is focused only on macroplastics and to date there are not similar dedicated regulations for microplastics. Although farmers are keen to address marine litter and plastic waste, microplastics are not generally of interest because they represent issues that are currently considered almost impossible to manage at the farm level.

The limitations of recycling also represent a challenge for farmers. For example, plastic products used in aquaculture operations frequently contain chemical additives that cannot be handled by all recycling facilities or include biofouling that may limit the ability to recycle the material. Most recycled plastics from aquaculture operations will be repurposed into materials for the construction industry. Many countries currently lack capacity or access to recycling facilities and governments should consider ensuring that recycling capacity grows to meet increased demand from industries such as aquaculture.

Actions to limit the use of plastic are of interest but all plastics cannot be removed from aquaculture operations without economically viable solutions as alternatives. To be successful, there is a need to bridge gaps between practitioners and regulators to ensure that industry needs are considered and the cost incurred by changes in operations are shared among all stakeholders.

Although not a specific focus of the roundtable, delegates participating in discussions showed interest in the potential for bioplastics and degradable plastics in the context of aquaculture (as user or producer). This topic will need further discussion. From the perspective of sustainable development, there is a research and development focus on biodegradable plastics with additional potential for expansion into bioplastics. All over the world these solutions are now being explored. These plastics may be developed as part of recycling strategies and bioplastics may be produced from organic wastes or seaweeds. Such development allows production of plastics that are capable of degrading over a few weeks. However, much more research is needed in this field to better understand the challenges and viability as an effective solution, especially with regards to supporting the necessary scaling up of such production and the evaluation of such products for use in aquatic environments. In many respects, there is a will from the aquaculture industry to use bioplastics and biodegradable plastics but the means is not yet there and much more research is needed to replace some of the non-replaceable plastics used nowadays. Although too much is unknown at this stage regarding the potential for alternative materials, if the industry can demonstrate a demand, there is scope for development and implementation of new engineering and technology solutions.

Examples of plastics debris collected as part of a Marine Clean-up Day organized by the Maritime and Port Authorities of Singapore. The southern areas of Singapore are not intensively farmed and and therefore most debris cannot be attributed to aquaculture (Photo: G. Drillet).

The impacts of plastics on aquaculture production are complex, with animals affected differently depending on species, size and life stage of the farmed animal, size of the plastics and the mix of chemicals they may contain. Mesoplastics may not represent a risk to farmed aquatic animals because they are unable to pass alimentary and respiratory barriers because of their large size. However, aggregations of microplastics in the stomach and intestines can result in reduced nutritional state and scope for growth in some species but not in others. In contrast, a varied picture is presented by ultrafine micro- and nanoplastics that are able to cross the gut barrier and have been linked to changes in growth and tissue formation in some species.

In addition, there is current debate surrounding the transfer to organisms of harmful chemical additives to plastics, including those no longer produced but still existing in plastics lost at sea and hydrophobic contaminants (e.g. polycyclic aromatic hydrocarbons; PAHs) already present in the natural environment that preferentially adsorb to plastics in the water column. Although there is the potential for these chemicals to be assimilated by an animal upon ingestion, this effect may be limited by the amount of time that the plastic is present in the gut, the levels of these chemicals already inside the organisms and exposure from the same chemicals in food and the surrounding water. Despite the level of uncertainty, potential impacts on the profitability of farms, whether from a direct impact on the product or indirectly from consumer perception of the product, must be established and mitigated where possible.

Routes by which micro- and nanoplastics may affect aquaculture production and the value of the resulting product include environmental exposure from airborne, waterborne or sediment plastics, and that originating from the exposure of other organisms subsequently processed into feed. The potential for exposure and uptake has been explored in many recent studies focusing on microplastics (0.1 μm to 5 mm) and nanoplastics (<0.1 μm) in the environment and in feed. The size limit between microplastics and nanoplastics is being discussed intensively. During the roundtable, nanoplastics were defined as plastics capable of passing intestinal epithelia (~0.1 μm). The rationale behind this decision was to organize discussions around what can be measured, separating impacts by the biological (at the organism level) or physiological (at the cellular level) effects. Nevertheless, where microplastics are found, nanoplastics are likely to be present as well.

There are currently no standardized methodologies for sampling and analysis of plastics from established authoritative sources (e.g. ISO, EPA, APHA, AFNOR) due to the varied requirements for sampling methods in different aquatic environments such as extractions from sediments or water, and a lack of standardized terminology in this emerging field (e.g. nano- vs microplastics). The requirement for an understanding of plastics input to the environment from wear and tear of common aquaculture infrastructure and products (tanks, pipes, liners, etc.), as well as the plastics found in feeds, requires serious investigations from the research community and feed manufacturers.

Data is starting to emerge and recent publications have reported that microplastics have been found in fishmeals. On a global scale, this would be a substantial number and therefore many aquafeed companies are actively looking at measures to prevent the occurrence of plastics in fishmeals. However, existing methods may only help to detect a limited size range (e.g. microplastics but not nanoplastics), complicated by the fact that different methods will generate different results for the same product. It is not clear today whether some of these microplastic particles are, in addition to deriving from forage fish biomass, are also emerging from the raw material used for extruding the feed or from degradation of feed bags. With an estimated 1.2 billion feed bags generated per year for the Asian market alone, this could introduce a significant risk. Nevertheless, the risk may be completely controlled as soon as the feed industry is aware of it.

In a recent report from the FAO (Technical Paper 615), 7 μg of plastic particles is estimated to be present in every portion (225 g) of mussels reaching a consumer’s table. At present, accumulation of microplastics not passing through the gut membrane in filter feeders is seen more as a consumer perception issue rather than a significant health risk. The accumulation of plastic particles in filter feeders and communication of the associated risks may hinder the development of molluscan aquaculture in areas where high exposure to plastic particles may occur. On this point, it is generally accepted that the presence of plastics in the aquatic environment is going to remain, even if the production of plastics upstream was immediately stopped and management of plastic waste was immediately started. Therefore, understanding oceanographic conditions, mapping the sources of microplastics, coupling particle tracking models with adequate monitoring plans and understanding how waste may accumulate in areas where filter feeders are produced is of interest for selection of production sites.

The presence of plastics in aquatic organisms is an important component of the communication of results of research studies on marine litter, and this has raised significant concerns from consumers. However, this is rarely considered in context and compared to the presence of plastics in other food products consumed globally (e.g. vegetables, kitchen salt, beer and bottled waters), where commercial laboratories have already been carrying out monitoring for decades. Asking aquaculturists to evaluate the amount of plastic in their products while not asking the same of producers of other food products reaching consumers’ tables will be de-incentivizing for farmers trying to implement plastic management practices.

The challenge faced by industry, academia and regulatory bodies today is that standardization does not exist because the questions and challenges are not clearly defined. A number of methods are needed to answer the diverse questions related to plastics and aquaculture. For example, the methods required for sampling, extraction and analysis of mesoplastics and larger microplastics (>5 μm) are unsuitable for smaller microplastics (<5 μm) and nanoplastics. Importantly, a wide range of sampling, extraction and analysis methods exist, but are not directly comparable, meaning data generated by different methods are not comparable. Much of the current discrepancy in sampling, extraction and analysis approaches is the result of the goal of achieving highly accurate and robust characterization regarding the origin, fate and composition of plastics, which are common questions in academic research. This diversity of highly specialized and costly approaches does not lend itself to routine monitoring and their outcomes are seldom comparable. Fortunately, coarser, more broadly applicable methods do exist.

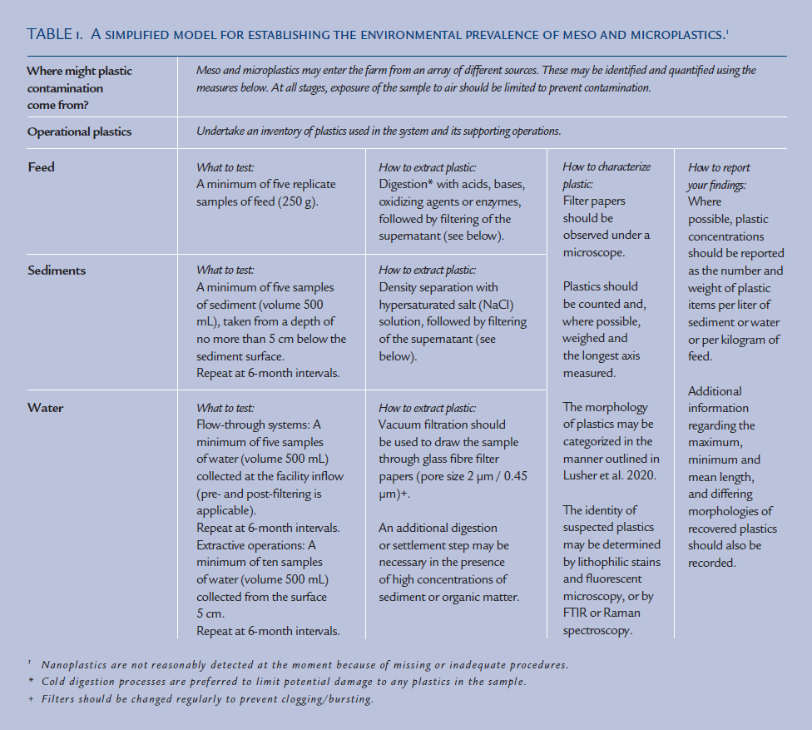

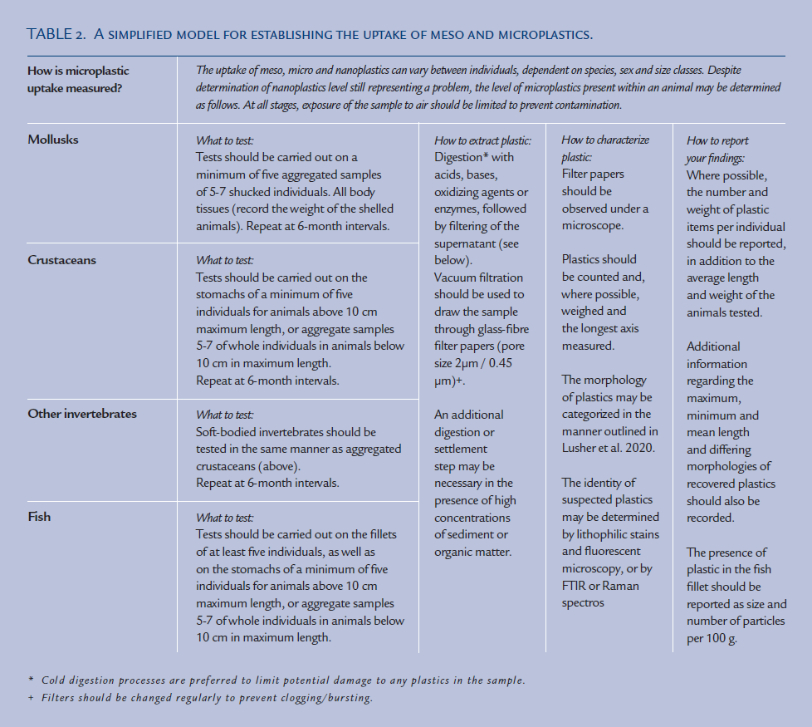

It is, therefore, important to slowly implement best practices to start creating a process of standardization and comparability of information: What are we measuring? In which matrix? For what reasons? In which unit are the results to be produced? To support changes towards more sustainable aquaculture, from production to food safety, stakeholders dealing with the source and impacts of plastics in aquaculture need to better define what problems are to be dealt with, in which segment of the industry they originate from and what is feasible to evaluate and monitor. In Table 1 and 2, we highlight a number of questions that may be of interest to quaculture and identify widely used protocols that are considered suitable to answer these questions. We also indicate the potential pitfalls of these approaches. There is a need for standardization, but this needs to be operationally viable, starting simply and implementable globally.

Changes necessary for aquaculture will occur as multi-sectorial change, including technology developers, equipment providers, third-party accredited testing laboratories, certification schemes, regulations and incentives for change supported by governments. Community and even general public perceptions can also have a significant influence. However, this typically varies across different regions/cultures and, although it is not always a limiting factor, communication is crucial to implement the changes needed to achieve more sustainable use and reduction of plastics in aquaculture.

At this stage, it seems important to create a baseline in an environmental context and to keep things simple. There are two main monitoring needs: the presence/weight/types of plastic among sites and the long-term trends at individual sites. This is knowledge that will allow governments to map sources and responsibilities for the presence of microplastics in the environment, as well as the effectiveness of implemented mitigation actions, thereby creating a basis for regulations. In terms of food safety, there are still many questions regarding the accumulation of micro- and nanoplastics in products of aquaculture and the role of plastic chemical additives. Thus, it is currently difficult to engage with either regulators or farmers on this topic at this stage.

Plastics represent a two-fold challenge in aquaculture, where aquaculture production represents a source of environmental release and where aquaculture is affected by plastics in the environment. Proposed changes to be implemented, such as inventory and monitoring, need to be supported by financial and technological incentives and by the various stakeholders (e.g. technology providers, laboratories, governmental agencies, feed and nutrition companies). Although aquaculture has a role to play in reducing plastic emissions to the marine environment, the fact that 80 percent of marine plastic derives from terrestrial sources highlights the need for wider, societal-level action on this problem. Thus, engagement with farmers is an important challenge that needs to be carefully managed. Aquaculture is the livelihood for 20 million farmers worldwide and cooperation toward more sustainable food production system is a necessity.

Based on fruitful discussions from the first event, delegates expressed interest in continuing to share information and define areas where actions can be initiated and others where the need for research is critical. The roundtable is expected to continue as part of the WA2020 conference in Singapore (14-18 June 2021), including a dedicated theme within the program and another planned roundtable for more targeted discussions. Submissions from across the sector are encouraged to highlight the perspectives of multiple stakeholders and to provide a platform for the community to come together and discuss new practical, technical and legislative solutions relating to plastics in aquaculture. For further details please contact Guillaume.Drillet@sgs.com for #WA2020.