WWW.WA

S.ORG

WWW.WA

S.ORG

•

WORLD AQUACULTURE

•

DECEMBER 2014

41

small-scale models mimicking

a simplified aquaculture net pen.

The models were manufactured

using the low-cost, rapid

prototyping capabilities

offered by modern 3D-printing

technology, capable of a spatial

resolution of 20 µm. This

method guarantees precision

and regularity of twines and

mesh, allowing us to modify the

geometry by microns. Thirty

circular pen models, with a

surface porosity varying from

0.56 to 0.90, were manufactured

(Fig. 1). As a point of reference,

typical aquaculture nets have

a porosity of about 0.80. Data

were acquired using dye

visualization, Particle Image

Velocimetry and unidirectional

load cell measurements.

Observations

Despite using a small-scale

model at low inflow velocity,

the observed flow behavior

was in good agreement with

larger-scale experiments and

numerical simulations (Klebert

2013). Varying the net-pen

porosity serves to vary the bleed

flow velocity (Wood 1967),

designated as U

1

, which is the

reduced velocity flow in the

wake of the model as a result

of the flow through the porous

surface at the back side of the

obstruction. Our models are

able to recreate the types of flow

expected in the wake of this

kind of geometry:

•

Regime 1 flows - A laminar steady wake with a bleed flow

velocity (U

1

) that is close to the free flow velocity (U

∞

).

•

Regime 2 flows - A steady wake of finite length that evolves

into an oscillating shear layer and subsequent vortex shedding.

•

Regime 3 flows - The bleed flow velocity is a small fraction

of the free flow velocity, resulting in high velocity gradients and a

shear layer developing into the classic von Kármán vortex shedding

pattern (Williamson 1996).

The mechanism for generation of a particular flow regime is

related to the porosity of the net pen. A very porous pen will have

regime 1 flow (Fig. 2 top) and a nearly solid pen will generate a

regime 3 flow (Fig. 2 bottom). However, porosity is not the only

parameter determining the wake, as two net-pen models of identical

porosity but different twine/mesh ratio can produce different flow

dynamics and significantly different drag.

Environmental

Aspects

The netting density

of a pen, usually imposed

by the need to retain fish

of a specified size, plays an

important role in the operation

of a net pen. It dictates the

oxygen supply rate to the

pen from inflowing water

and the rate that wastes are

flushed through the pen. The

dispersion of biosolids is

directly related to the flow

regime and the magnitude

of the bleeding flow. Net-

pen models with the first

flow regime have the fastest

diffusion time, whereas

models with the third flow

regime tend to trap particles

in their wake for an extended

period. To consider the issue

of waste, this may have an

impact on fish health, as in

the case of waste returning to

a net pen with a turning tide,

which is not preferable.

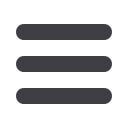

Impact on Drag

We conducted multiple

experiments, each varying

only one parameter: twine

thickness, the mesh void or

porosity. The results indicate

the following trends:

•

An increase in the

mesh void tends to result in a

reduction of drag. However, a

void that is too small induces

more drag than a completely

opaque net (Fig. 3).

•

A reduction of twine thickness does not necessarily lead to a

reduction of drag. Regardless of twine thickness, it is always possible

to identify a net-pen model porosity with a greater drag than an

opaque net (Fig. 4).

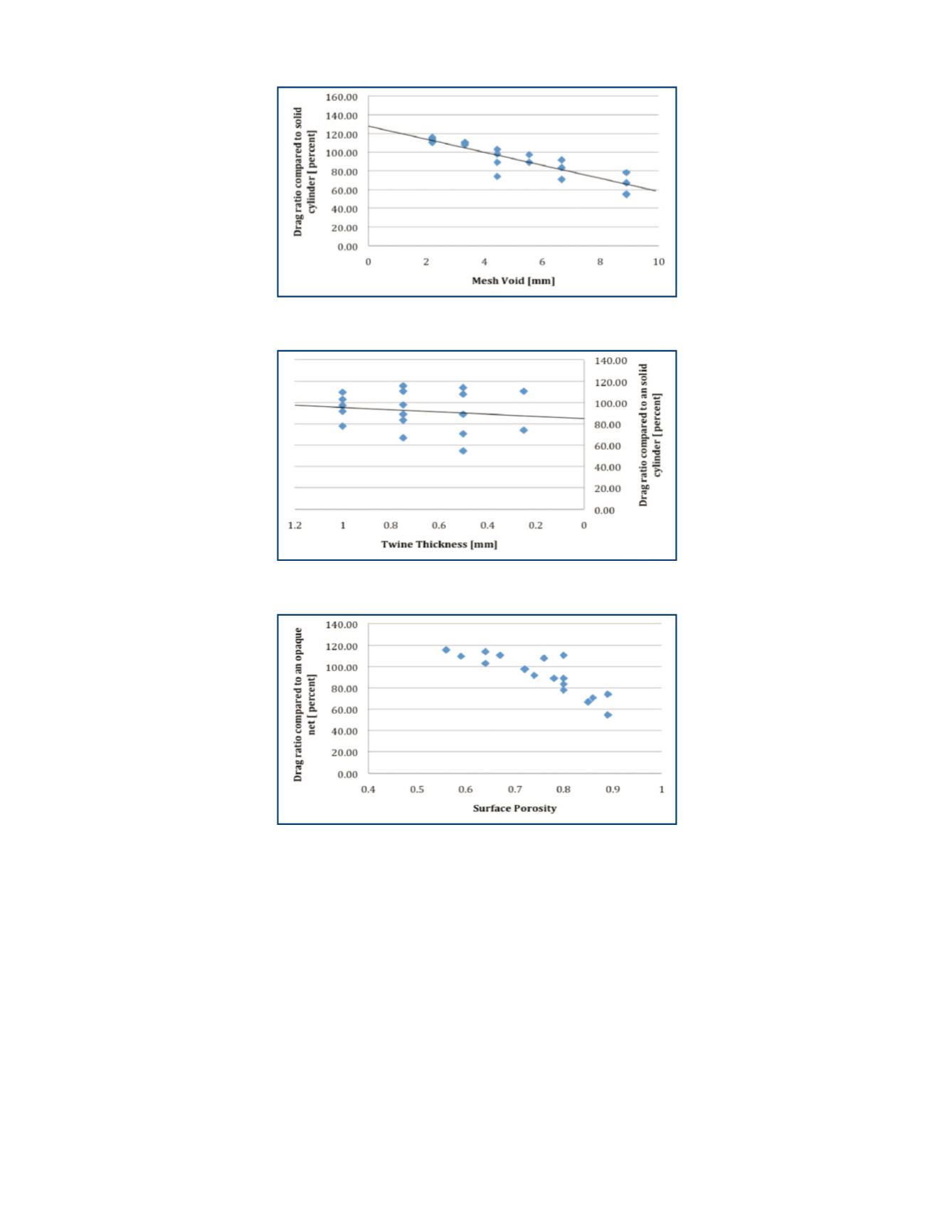

•

An increase in net porosity does not necessarily induce less

drag. The same drag was obtained with models of surface porosity

varying by over 40 percent (Fig. 5).

Based on these results, we infer that the induced drag on a

net pen produced by the net cannot be determined by the surface

porosity parameter alone. Although mesh void is the dominant

parameter driving the mechanism, generating drag, the effect of

twine thickness cannot be overlooked.

We are currently revising the mathematical model which,

if verified on a larger-scale aquaculture net-pen model, could

( C O N T I N U E D O N P A G E 4 2 )

FIGURE 5.

Drag of various net models as a function of the surface porosity E.

FIGURE 4.

Drag of various net models as a function of the twine thickness.

FIGURE 3.

Drag of various net models as a function of the mesh void.