40

DECEMBER 2014

•

WORLD AQUACULTURE

•

WWW.WA S.ORGS

ince the early 1980s,

there has been an exponential

growth in the quantity

of seafood produced by

aquaculture and, in the near

future, this production will

account for half the world’s

global harvest of fish. With ever-

growing demand, fish farms are

trying to expand. Countering

this expansion is growing

concern, globally, on the

potential environmental impact

of larger aquaculture farms.

As a result, many governments

are becoming reticent to grant

new concessions to aquaculture

developments in coastal waters.

Consequently commercial

producers of marine finfish

have been seeking alternative

locations to coastal bays,

fjords or other areas to locate

larger net-pen farms. Moving

further offshore appears to be

the logical alternative, making

farms invisible from the coast,

reducing their ecological and

environmental impact on

coastal marine life and also enabling the installation of wider and

deeper pens.

Inevitably this expansion raises a number of new requirements:

increased operating costs, on-site maintenance personnel, energy use

and net-pen design. Existing pens may be unsuitable for the harsher

conditions found in the open ocean, where mooring lines must resist

large fluctuating forces and high induced drag generated by waves

and currents. Exploiting wave action to provide autonomous wave-

powered energy system for aquaculture farms is being explored

currently (Meggitt 2014). Failure of mooring lines caused by over-

loading often leads to net loss, resulting in ‘ghost nets’ that can pose

a threat to marine life and a navigation hazard. Furthermore, an

increase in climatic variability seems likely to lead to an increase in

ocean wave states.

Considering future changes in environmental conditions,

the compounding problems of increasing pen size and the lack of

natural shelter in the open ocean, new farms must increase their

capabilities to withstand degradation and major mechanical fatigue.

The interaction of the net with water flow from waves and currents

govern the resulting forces. This is an area where efforts can be

The Impact of Net Density

on Oceanic Aquaculture Pens

Benjamin Levy, Heide Friedrich, John Cater, Richard Clarke and James P. Denier

made toward optimizing the

net structure (mesh/twine

composition or ‘weave’) and

the relative location of a pen

within a concession.

In addition to the

mechanical action of water

flow, there is the associated

problem of bio-fouling,

which can serve to reduce net

porosity by over 50 percent,

with direct consequences for

fish health through a reduction

in the rate of oxygen supply.

Another major impact of

biofouling is the resulting

drastic increase of drag forces

on the structure, increasing

tension in mooring lines or

towing cables.

These combined factors

have motivated a deeper study

of aquaculture net drag and

how it may be minimized.

The considerations presented

here must be taken together

with certain practical issues

such as the constraint of the

mesh void size in relation to

fish size and the need of the twine thickness of the mesh to support

mechanical stress.

Technical Aspects

Within the Faculty of Engineering at the University of

Auckland, we are undertaking a study of the impact of net density

on flow dynamics and drag, where variations in the mesh void (i.e.

the space between two consecutive twines) and twine thickness are

being investigated. To better quantify the effects of design changes,

a small-scale experimental investigation was conducted within our

Fluid Mechanics Laboratory, where changes can be evaluated under

well-defined and controlled flow conditions.

Experimental data were acquired using a recirculating flume

with a measured turbulence intensity of less than 3 percent. The

flume cross-sectional area is 0.4 m by 0.4 m, with a length of 4

m and an operational flow rate between 2 and 50 cm/s. Under

these controlled conditions, it has been possible to obtain detailed

measurements of the flow dynamics for a range of models with

varying mesh and twine dimensions.

Rather than studying a section of a net, we manufactured

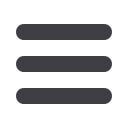

FIGURE 1.

Three net-pen models with varying mesh and twine dimensions.

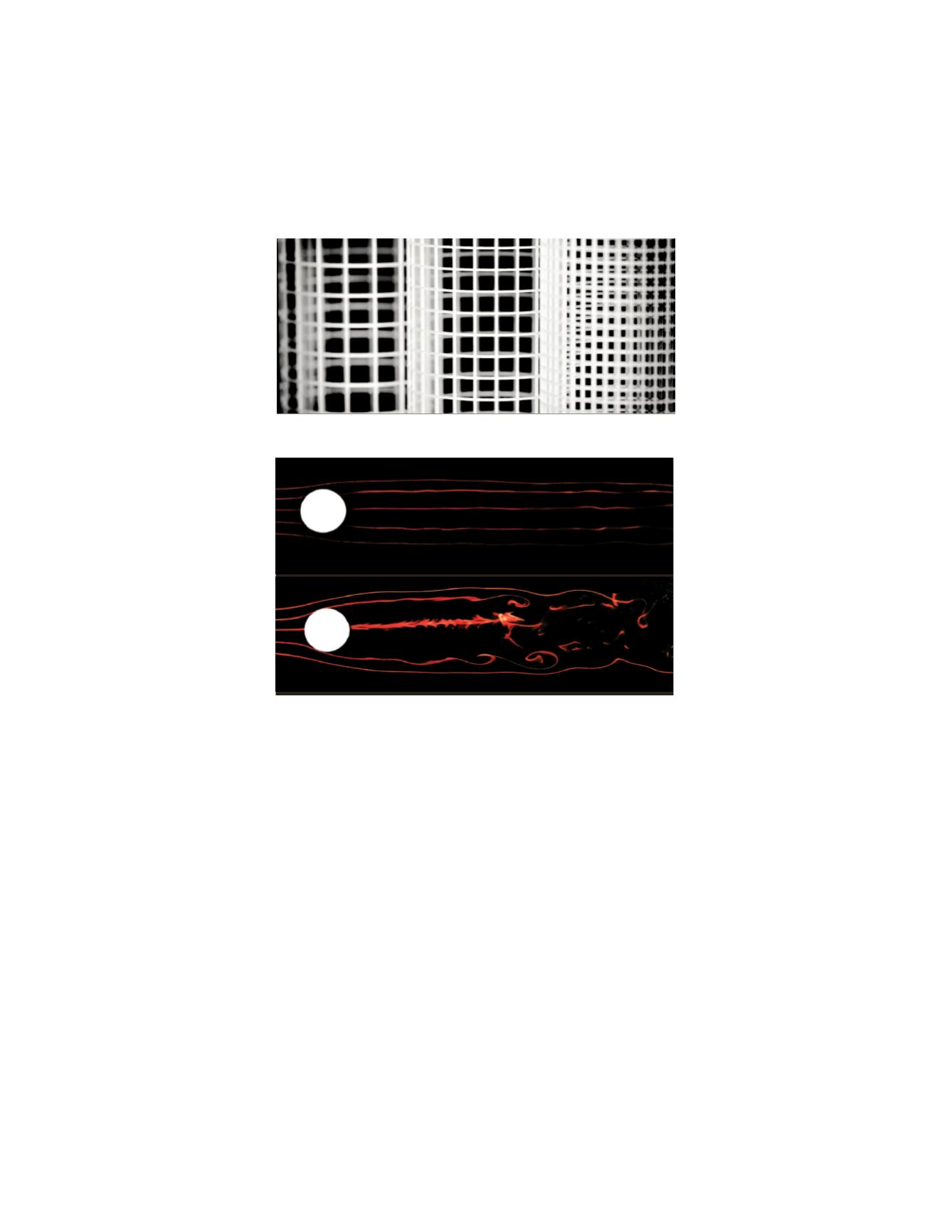

FIGURE 2.

Flow regimes obtained from two models with the same mesh void size but

differing twine thickness. The increase in twine thickness reduces the bleed flow velocity

which results in greater velocity gradients that evolve into an unstable wake (lower image).