MICROBIAL AQUAFEED PRODUCTION FROM LIGNOCELLULOSIC SIDESTREAMS VIA AN AEROTOLERANT CELLULOLYTIC CONSORTIUM

Lignocellulosic biomass is globally abundant, and can be found in food manufacturing side streams and post-harvest residues, representing a promising feedstock for microbial bioconversion to food and feed ingredients, and this is of particular interest for the international aquaculture industry

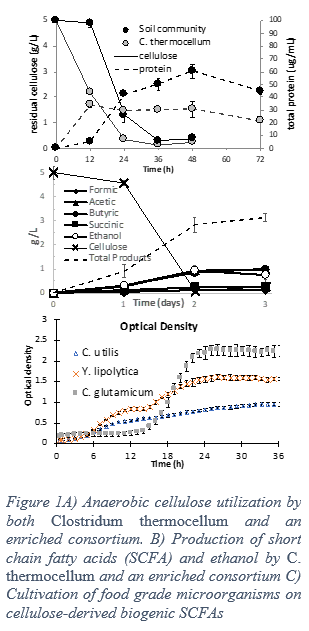

However, recalcitrance of these materials has limited their application, and pretreatment, sterilization, and enzymatic hydrolysis are bottlenecks to economic feasibility. Through consolidated bioprocessing, aerotolerant thermophilic cellulolytic consortia can be applied to overcome these challenges, achieving rapid and complete cellulose conversion into short-chain fatty acids (SCFAs) in less than 48 hours (Fig 1A-B).

These SCFA cocktails have now been confirmed to be an excellent substrate for the growth of food grade strains such as Candida utilis, Yarrowia lipolytica, and Corynebacterium glutamicum. C. utilis has been shown to produce up to 30 g/L cell dry weight when cultivated on SCFAs in bioreactors, with 43% protein and 18% lipids containing up to 50% polyunsaturated fatty acids. (Figure 1C)

Importantly, the selective thermophilic and anaerobic conditions of this mixed culture process can be performed without sterilization, which could significantly reduce processing cost. The cellulose-derived microbial biomass demonstrated here represents a previously untapped marine-free aquafeed ingredient, and can contribute to increased food security and a circular bioeconomy.