REVIEW OF NON-TOXIC AND MECHANICAL PRE-TREATMENT PROCESSES TO PREPARE NATIVE CHITIN FOR HIGH-STRENGTH NANOMATERIAL APPLICATIONS

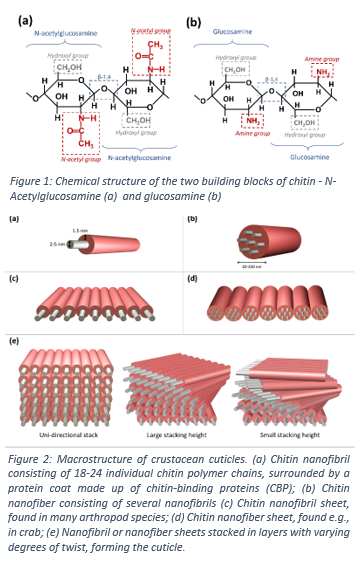

Chitin is a polymer chain of N-acetylglucosamine and glucosamine. It provides structure and stability to the exoskeleton of crustaceans, insects and fungal cell walls. Intermolecular hydrogen bonds between polymer chains create a very tight crystalline fibre network with excellent mechanical properties. Chitins’ antimicrobial properties and high biocompatibility make it an attractive polymer source to produce nano-materials such as gels, fibers, or films

To date, commercial utilization of native chitin has been limited due to its insolubility in aqueous solutions and most common solvents. Instead, chemical modifications such as deacetylation (conversion to chitosan) or depolymerization are used to make chitin soluble and easier to work with but consequently, chitin loses some of its mechanical stability. Other approaches for chitin dissolution employ toxic chemicals, potentially preventing its use in biomedical and food applications. Studies in recent years have produced several environmentally-friendly and non-toxic pre-treatment processes which can reduce chitin’s crystallinity and tight macrostructure without destroying or changing the native polymer chain. This review (oral or poster) will begin with a description of the macrostructure of crustacean cuticles, followed by a summary of non-toxic and mechanical pre-treatment processes which can be applied to prepare the fiber for nanomaterial applications. The effects of macrostructure on pre-treatment are discussed.