FISH SLUDGE – A PROBLEM OR A RESOURCE?

Fish sludge from land-based aquaculture facilities can be considered The Elephant in the Room, if this problem is not addressed and handled it can be a barrier for new land based project and further growth in marine food production. Fish sludge consists of feces and food waste from the production in the aquaculture facility, and is high on phosphates and other important minerals that is essential for sustaining life on the planet. Fish sludge also contains heavy metals such as zinc (Zn) and cadmium (Cd) and can thus not be used as is for fertilizer without special treatment and regulations. To be able to reach the climate goals, reuse of minerals such as phosphorus in a circular economy is essential, and we can simply not continue to waste thousands of tons of fish sludge every year.

Treatment of sludge in land-based aquaculture often consists of mechanical dewatering from 0,1 DS (dry solids) to around 15 % DS before it is transported to a biogas facility. Because the aquaculture sites often are far away from the biogas plants, this means transporting enormous amounts of water every year. This is highly expensive and not sustainable because it results in thousands of transport mileages. The use of fish sludge in production of biogas also results an high volumes of bio rest materials, with concentrated heavy metals.

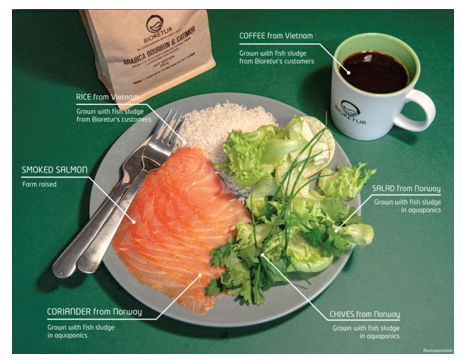

The Norwegian company Bioretur offers a solution to the fish sluge problem and gives fish farmers access to the best available technology for sludge treatment for the aquaculture industry. At the same time they get a partner who ensures that the sludge is transformed from a problem to a sustainable resource. Bioretur are experts on sludge, and their value proposition is that for a fixed monthly fee they build, operate and maintain the technology of sludge treatment, while the client do what they do best: Produce high quality fish and seafood!

For the fist time, Steinar Wasmuth will present the Bioretur concept in Canada.