COMPARATIVE ANALYSES OF DRYING PROFILES AND ECONOMIC OUTCOMES OF SMOKE-DRIED CATFISH Clarias gariepinus USING TRADITIONAL AND STANDARDIZED ECO-FRIENDLY KILNS IN LAGOS, NIGERIA

Fish is a major source of animal protein in a developing country like Nigeria and its shelf life is most commonly lengthened by smoke-drying using Traditional Drum Kiln (TDK). Two major challenges of using TDK however are subjective processing process and paucity of documented economic data involved with its use. The aim of this study was to standardize TDK, construction of Eco-Friendly Kiln (EFK), identification of market characteristics, assessing of total costs and estimation of revenue generation from smoke-drying catfish (Clarias gariepinus) in eight selected fish markets in Lagos, Nigeria.

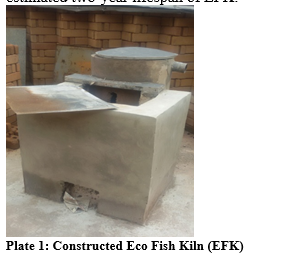

TDK was constructed as used in the selected fish markets measuring 72 cm height and 55 cm diameter while EFK was constructed starting with TDK and then fortifying it with refractory lagging material comprising of clay, sawdust and silicon carbide in ratios 4:2:0.5 to form the drying chamber where the fresh fish were arranged for the smoke-drying process. An aperture with dimensions 60 x 20 cm was cut at the front and a flame chamber with dimensions 93.1 x 77.5 x 85.2 cm was built with red bricks and coated in and out with the refractory was assembled in front of the drying chamber. Smoke filters of sizes 0.1 and 0.3 cm were fitted in the aperture to control the amount of smoke particles entering the drying chamber from the flame chamber. A smaller aperture with dimensions 29.6 x 16.8 cm was cut at the bottom middle to accommodate the burning fuel (dried red mangrove) (Plate 1). Market parameters, total costs and revenue generation in eight fishing villages in Lagos State were investigated and smoke-drying was done at a stretch of an average of 24 ± 3 hours. The standardization of TDK and EFK was done by maintaining the smoke-drying temperature in both kilns between 60 0C and 80 0C with the use of temperature sensor, audio smart alarm and Light Emitting Diode.

EFK fitted with two layers of 0.3 smoke filters was found to have the highest quality smoke-dried from the drying profile. The market characteristics indicated that smoke-drying process was predominantly carried out by women with little formal education and there were differences in the mechanics of fresh fish procurement, processing methods and marketing channels. The cost and revenue estimation using both kilns showed that the use of EFK had significantly greater turnover and would generate about ? 2,715,752 as compared with ? 1,127,752 with the use of TDK over an estimated two-year lifespan of EFK.