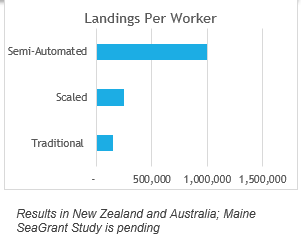

A SEMI-AUTOMATED OYSTER GROWING SYSTEM; ONE-MILLION LANDED OYSTERS PER WORKER YEAR PER AT A LOWER COST

- Equipment Loss and Damage

- Gear permanently attaches to the 24mm polypropylene rope, in use for 4 years

- Low maintenance on gear

- Fouling Control

- Oyster and gear hygiene is fast

- The ease of controlling biofoul permitted scaling landings per worker

- High Staff Cost and Turnover

- Reduced by 75%.

- Now attracting staff with a wider range of capability

- Predator Abatement

- Flatworm and mud worm impact was essentially eliminated by the ability to keep gear much cleaner.

- Bird/Animal predation was reduced.

- Maximized Space

- Grading at the farm site with a small barge reduced land needs.

- Variable Growth

- Oyster shape was more uniform due to shape of baskets and movement of basket.

Food source improved by increased waterflow from perpetually clean gear.