THE EFFECTS OF CARBON/NITROGEN RATIO ON SUSPENDED GROWTH DENITRIFICATION IN REUSED BRACKISH AQUACULTURE WATER

Nitrate accumulation is a key limiting factor in water reuse for RAS, as high concentrations result in negative impacts on aquatic animal production. Traditionally nitrate is removed by water discharge from the system, potentially causing negative environmental impacts and increasing production cost. This is especially true for inland brackish and marine aquaculture, where salt can be a significant expense. Another means of nitrate removal is denitrification, a method in which nitrate is ultimately reduced to dinitrogen gas, which is then harmlessly released into the atmosphere. Among the more common methods of denitrification are fixed film bioreactors which utilize media to provide a substrate for bacterial growth. However, the media and bioreactors can be expensive and take up valuable space within the production facility. The purpose of this study was to evaluate a suspended growth (biofloc)-based approach to denitrification using ethanol to achieve different C/N ratios.

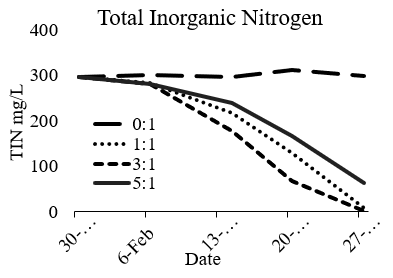

Four different C/N treatments (5:1, 3:1, 1:1, no added carbon) were tested in triplicate using 150 L tanks filled with reused water from a commercial L. vannamei biofloc production system. The initial nitrate concentration was 296 mg NO3-N/L which comprised all but about 0.3 mg/L of the total inorganic nitrogen (TIN), and salinity was 15 g/L. Carbon in the form of 95% ethanol (provided by Beam Suntory, Inc.) was added daily based on the previous week's TIN results. TAN, nitrite, nitrate, phosphate, alkalinity, sulfide, TSS/VSS, and turbidity were each measured weekly, and DO, pH, salinity, ORP, and temperature were determined daily.

The study ended after 27 days when total denitrification had been observed in some tanks. Both the 3:1 and 1:1 treatments showed significantly higher rates of denitrification than the 5:1 treatment. The 3:1 treatment showed total nitrate reduction of 294 mg/L and the 1:1 treatment showed a total reduction of 287 mg/L. The 5:1 treatment reduced nitrate by 280 mg/L but showed significant nitrite accumulation of 49 mg/L, and only reduced TIN by 232 mg/L. These results show the potential of suspended growth denitrification without the use of external bioreactors and indicate the optimal C:N ratio may be between 3:1 and 1:1.