CLEAR-WATER FIXED FILM CAROUSEL PRODUCTION OF MARINE SHRIMP

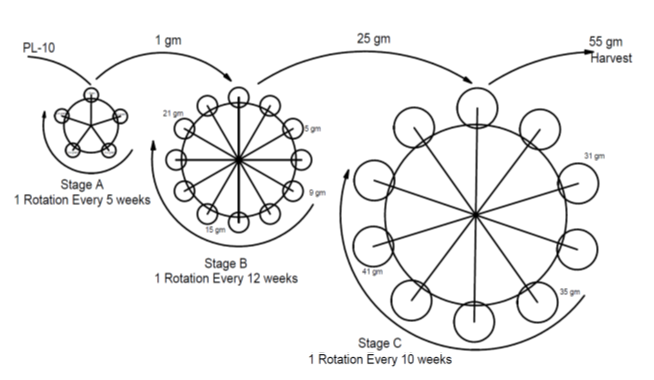

Conceptually a "carousel" consists of a cluster of tanks dedicated to shrimp growth through a designated size category. Tanks and filters are sized to support the highest feed rate in the size class. Tanks in a given caro usel are "rotated" weekly until the shrimp complete the growth stage. Shrimp in the tank are then rotated forward to complete the next growth stage. Using fixed- film clear water technology, the c arousel design is specifically targeted to produce a reliable weekly supply of shrimp for local sale. The carousel concept was generated as part of a USDA Small Business Innovative Research (SBIR) grant directed at improving indoor recirculating technologies to produce shrimp in tanks where temperature preclude pond production. The grant focuses on improvement of shrimp production densities in tanks supported by airlifted floating bead bioclarifiers. Weekly production targets in the range of 200-300 pounds are obtainable using polyethylene tanks and filters with production densities presumed at 10 kg/m3. The number of RAS required range from 16-20, depending on the growth rate equations. Issues confronting potential producers include availability of p ost larvae for regular stocking of Stage A tanks, availability growth curves, and detection of food consumption deviations during growout.