AUTOMATED BIOFOULING CONTROL OF AQUACULTURE OYSTER CAGES AND CROP

The Aquaculture industry provides essential food to the growing world population, especially in the supply of protein to low-income and food deficient countries

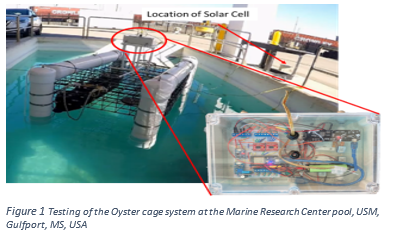

. Biofouling is a major problem in a quacultural production as both the target culture species and/or infrastructure are exposed to a diverse array of fouling organisms. This problem has been partially mitigated over the years by manually lifting or flipping infrastructure like oyster cages periodically above the waterline though it is labor-intensive and costly. This is to expose the cro p as well as the farm equipment in the air and sun to minimize biofouling. Automated oyster cage operation would help in the reduction of manual labor and increase productivity. It will address these challenges by providing remote control that can vertically move farm structures based on user input or predefined rules which can be based on any combination of time of the day, wave height, air temperature, humidity , wind, precipitation , and other weather conditions. Such flexibility allows optimizing the desiccation cycles for maximum farm production. An automated control unit has been developed that is comprised of low-cost air pumps, solenoid valves, solar cells, microcontrollers, and other electronics, as shown in Figure 1. The pumps allow automatic desiccation of the oyster cage by moving air into the side floats and bottom floats . This process lifts the cage above the water line into the desiccation position. The valves allow the air inside the floats to escape and water to re-enter the floats to sink the cage . As bottom floats are filled with water, top floats hold the cage right below the water surface in the feeding position . The s ide floats stabilize the cage during the transitions between feeding and desiccation position. T he sinking and raising of the system are controlled via an IoT (Internet of Things) microcontroller, i.e. , the cage is connected to the internet for remote operation. All electronics are powered by solar energy. The performance of the system is monitored via telemetry, which includes the Wi-Fi strength , cage state, pumps, and valves states, and battery voltage level . The telemetry also includes local environmental parameters like temperature and humidity inside the control unit . This study currently advances towards the development of a cellular data link to a master cage at the remote farm site and a local mesh network between the rest of the oyster cages. This will allow the far mer to adjust the desiccation times to the oysters' growth stage and react to weather events based on the local conditions and forecasts from internet-based weather services. Future research will focus on the refinement and ruggedization of the system and the optimization of the desiccation cycle.