A NOVEL ADVANCED OXIDATION TECHNOLOGY THAT RAPIDLY REMOVES GEOSMIN AND MIB FROM WATER AND SIGNIFICANTLY REDUCES ATLANTIC SALMON DEPURATION TIME

Atlantic salmon (Salmo salar ) reared in RAS can accumulate off-flavor chemicals (e.g., geosmin and 2-methylborneol, MIB) that reduce fish marketability. A solution to this problem is to finish the fish in separate depuration systems that are flushed with clean water in a single pass or operated with limited water recirculation. During depuration the fish are not fed and c an lose significant weight and value.

We tested the effects of a new technology called the Exciton Advanced Oxidation Process® (eAOP® ) on the removal of geosmin and MIB from 18 m3 depuration tanks at a commercial Atlantic salmon RAS operation. eAOP® is a unique technology that works using multiple mechanisms of action including UV photolysis, titanium dioxide photocatalysis, electrolysis, and UV/peroxide AOP. Geosmin and MIB were measured by GC /mass spectroscopy.

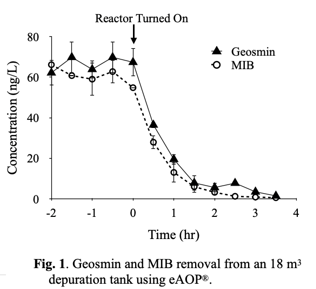

In p reliminary chemical spiking experiments without makeup water flow, the eAOP® reactor rapidly eliminated all of the geosmin and MIB in the water in 2- 3 hrs (Fig. 1). An actual depuration experiment was then conducted to determine the effects of eAOP® on the total purge time. Market-sized (4 kg) fish from a single harvest were split equally between control (normal flow-through depuration procedure) and eAOP® -treated 18 m3 purge tanks. W ater and triplicate fish flesh samples were collected from each tank every two days for ten days.

Geosmin levels in both groups followed first order removal kinetics with the following parameters: control tank fish, k = 0.092 day-1, R2 = 0.91, half-life = 7.5 days; eAOP® , k = 0.147 day-1, R2 = 0.95, half-life = 4.7 d. Thus, geosmin removal from the fish in the eAOP®-treated tank was 60% faster than in the control tank , and the normal 10-day depuration time was reduced to 4-5 days. We conclude that eAOP® can be used to treat purge water to significantly reduce total depuration times while using less water.